budget home kits

Forming Your Concrete Foundation Just Got “EZ”

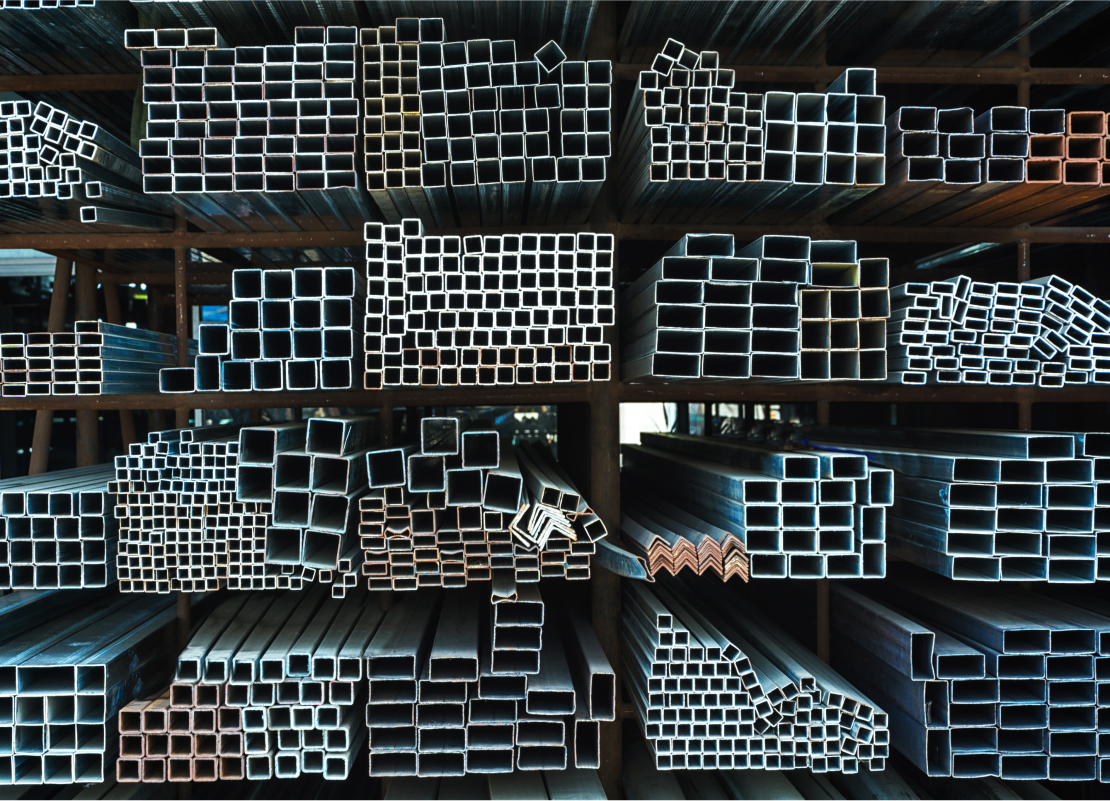

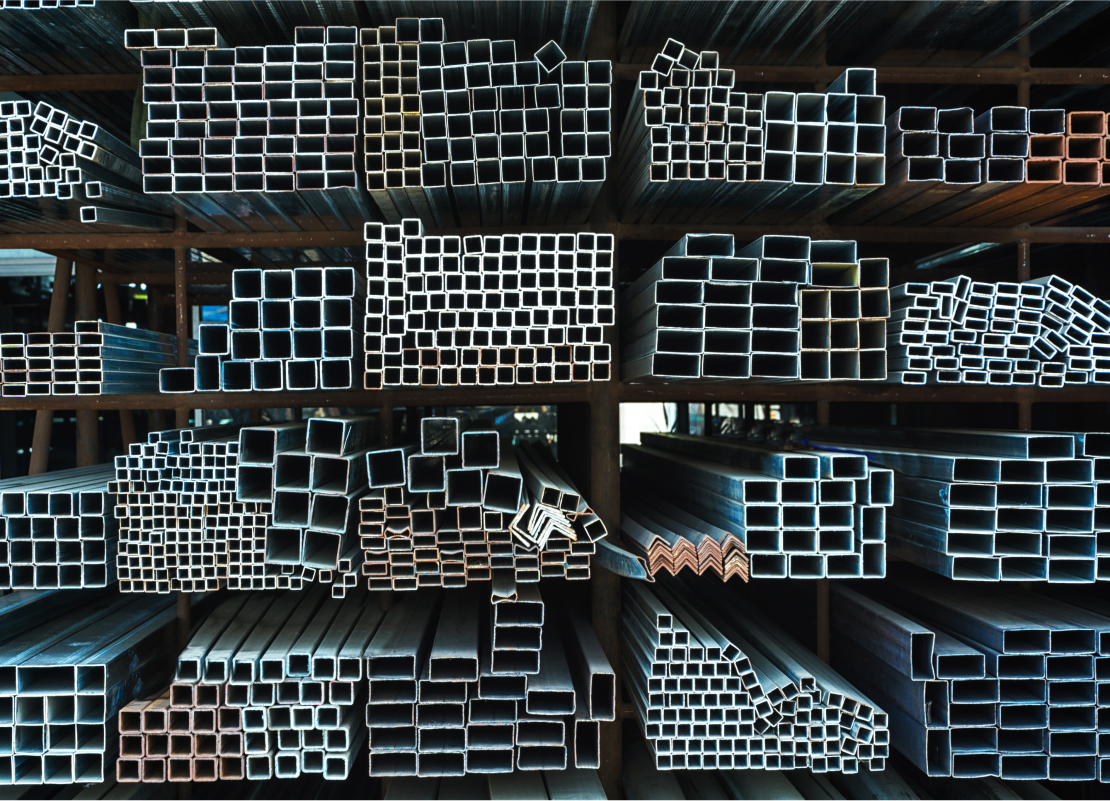

Another in the long list of features that separate us from other kit providers is our EZ-Form™ Integrated Steel Forming System. Our steel concrete forms are cut to length and easy to install. And unlike tedious, old-school wooden forms, our forms stay attached to your home’s framing, providing added strength, stability, and a nice straight steel edge.

budget home kits

What is the EZ-Form™

Foundation System?

There are three main stages to create the concrete slab for your home: Forming, Pouring, and Finishing. Hiring someone to build your slab will cost you more money each step of the process. Wouldn’t it be nice if you could circumvent at least some of those costs?

Forming

Forming your foundation means actually attaching the members that will create the perimeter barrier that holds the concrete in. Using our Assembly Guide and provided steel forms, you can complete this step yourself with surprising ease. The steel forms attach with framing screws to your galvanized column anchors, creating a superior straight edge that stays on for the remainder of the process. Hiring a conventional foundation contractor means paying extra for simple wood forms that will eventually get scrapped anyway.

Pouring

Along with the vertical edge that creates the concrete barrier, our forms also feature a top flange which represents the height of your slab’s surface. If you choose to pour it yourself, you simply pour concrete inside the forms until it is flush with the top flange. It couldn’t be simpler than that! This, by itself, is a great opportunity to save thousands of dollars.

Finishing

With the concrete poured to flush with the top flange, you simply need to float and trowel the surface. Even if you don’t feel comfortable doing this step yourself, you can hire a small crew to put the finish on a slab which you have formed and poured – realizing significant savings overall.

budget home kits

Traditional Foundation

vs Our EZ-Form System

| Conventionally Contracted | DIY Integrated Steel | |

|---|---|---|

| Timing | Measuring ground elevation, Squaring pad corners, Setting comer stakes, Component labeling and familiarization | Measuring ground elevation, Squaring pad corners, Setting comer stakes, Component labeling and familiarization |

| Specialized Labor | Extra fee to build and remove forms; More difficult to manage and maintain during the pour | Custom-cut steel forms; Simple to install – no specialized labor to build or pour; Hire finisher if desired. |

| Material Quality | Lumber of varied size & quality; Later disposed of; Addss no further structural support to home frame | #1 American galvanized steel; Permanently secured; Adds strength and stability to home frome |

| Cost | Market pricing for concrete foundation of 3,000 sq ft home with full-length from porch: $20,000 – $35,000 | By assembling our EZ-Form™ system and minimizing the amount of labor contracted – same slab: $5,000 – $10,000 |

budget home kits

Review: When

You Hire Concrete Contractors, What Are You Paying For?

Home builders can spend a significant amount of their early budget on the foundation of their home. That’s because they end up paying for not only the concrete but also the labor and lumber that go into forming up a conventional slab – not to mention the labor to put a finish on the top of the newly poured concrete. After it’s all cured, the wooden forms come off (exposing the side of the concrete) and simply get thrown away.

Our integrated steel forms offer you a better option for several reasons:

As you can see, our EZ-Form™ Integrated Steel Forming System differs in many ways from conventional wood concrete forms. Because of the superior steel materials, the ease of assembly, and the potential savings involved, we believe there’s really no comparison.